Freeze Dryer For Home for Dummies

Wiki Article

6 Simple Techniques For Freeze Dryer

Table of ContentsFreeze Dryer Fundamentals ExplainedThe Basic Principles Of Freezer Getting The Cooler To WorkEverything about Freezer

Freeze-drying or lyophilization is a dehydration method based upon the sublimation of water in a product (, ). This indicates that the product's water content transitions from a strong to an aeriform state or from ice to vapor without undergoing the liquid state (). Freeze-drying is considered a premium quality dehydration technique for a couple of reasons, consisting of (, ): it runs at low temperatures, which contributes to maintaining a product's nutritional worth, preference, look, and also heat-sensitive compoundsfreezing hinders chemical and microbiological processes, which considerably delays the product's wear and tear (thus prolonging its life span) Raw foods are consisted of about 80%95% water, which can be divided right into "cost-free" and also "bound" water.In the freeze-drying procedure, all cost-free water and some bound water should be gotten rid of, and also complimentary water needs to stay frozen at all times. This is the main difference between freeze- and also vacuum-drying and also the most difficult action (). The freeze-drying procedure can be divided right into 3 actions (,, ): The product is usually frozen under air pressure.

Likewise referred to as desorption drying out, it's the drying out of products to their preferred humidity by getting rid of the remaining bound water. Freeze-drying must be executed in regulated conditions that do not thaw the water, seeing that the visibility of liquid water might alter the item's composition, form, and physical buildings ().

Freeze drying happens in three phases: Freezing Main Drying (Sublimation) Secondary Drying (Adsorption) Appropriate freeze drying out can minimize drying out times by 30% Freezing is one of the most essential phase of freeze drying out, and there are several techniques for it. Cold can be done in a fridge freezer, a cooled bathroom (shell fridge freezer) or on a shelf in the freeze dryer (freezer).

Top Guidelines Of Deep Freeze Unfreezer

This maintains its physical type. Freeze drying is easiest to complete utilizing big ice crystals, which can be generated by slow cold or annealing. However, with organic products, when crystals are as well huge they may break the cell wall surfaces, which brings about less-than-ideal freeze drying outcomes. To stop this, the freezing is done swiftly.

Freeze drying out's last phase is second drying (adsorption), during which the ionically-bound water molecules are gotten rid of. By increasing the temperature level higher than in the main drying out stage, the bonds are broken between the product and the water particles.

After the freeze drying procedure is full, the vacuum can be braked with an inert gas prior to the material is secured. Many products can be dried to 1-5% residual wetness.

About Freezer Temperature

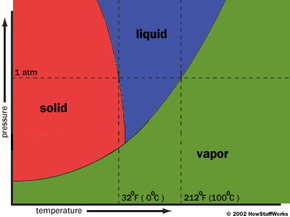

The essential concept in freeze-drying is sublimation, the shift from a strong directly right into a gas. Similar to evaporation, sublimation happens when a molecule gains sufficient energy to damage devoid of the molecules around it. Water will sublime from a strong (ice) to a gas (vapor) when the molecules have sufficient power to damage complimentary but the problems aren't right for a liquid to develop (freezer).For a material to take any type of certain stage, the temperature level as well as stress must be within a specific variety. The graph listed below programs the essential pressure and temperature level values of different stages of water.

06 ambiences (ATM MACHINE), the water is warm enough to thaw, but there isn't enough stress for a fluid to develop. It becomes a gas. This is specifically what a freeze-drying equipment does. A typical maker includes a freeze-drying chamber with a number of racks affixed to heating devices, a cold coil attached to a look these up fridge compressor, and also an air pump.

When you seal the chamber as well as start the procedure, the maker runs the compressors to reduce the temperature level in the chamber. The product is iced up solid, which separates the water from whatever around it, on a molecular degree, also though the water is still present. Next, the maker activates the vacuum cleaner pump to force air out of the chamber, decreasing the air pressure below.

Rumored Buzz on Cooler

Because the stress is so reduced, the ice turns straight into water vapor. The water vapor condenses onto the cold coil in solid ice form, in the exact same means water condenses as frost on a chilly day.

This allows food to become shelf-stable for 20-25 years. Yes, they are indeed amongst the extra pricey food preservation approaches. Examine out this article if you're trying to find my favorite. It is essential to understand that freeze drying out is different than drying out. Read this article if you're not sure of.

The various other day a friend asked me if I'm as thrilled regarding it as I was when I initially obtained it. Well, I'm also much more excited really, and also after that discussion, website here I went out and also bought a 2nd system! To be truthful, I wasn't extremely ecstatic concerning the freeze dryer at.

Report this wiki page